|

I was very excited when Highland asked me to do a review of some saws from Bad Axe Tool Works. I may be a little biased since I already own three of their saws. I have been extremely pleased with my saws and I was anxious to see how the saws that Highland Woodworking is now carrying, especially the new Stiletto Dovetail Saw, compare.

Before I begin looking at the saws, however, where did the name 'Bad Axe' come from?

Bad Axe Tool Works is located in Southwest Wisconsin in, as you may guess, the Bad Axe River Valley. Their website says, "...The Fox/Sauk American Indians, led by the indomitable War Chief Blackhawk, fought for this land against insurmountable odds during Andrew Jackson's Blackhawk War of 1832. Blackhawk's uncompromising standards of conduct, resilience, and leadership imparted an unyielding legacy to the land and the Amish and Scandinavian pioneers who settled it to farm the lush, rolling hills and hunt the coulees, and where their descendants today maintain a rich tradition of the woodworking and timber-framing crafts..."

Mark Harrell founded Bad Axe Tool Works in 2009 and says, "I have sought to imbue the saws I make with the spirit of the Bad Axe river region, and create a tool made of the finest materials available--a saw of enduring strength and beauty with which you may ply your craft."

This review will discuss three (3) saws from Bad Axe...(top to bottom in the picture) the Stiletto Dovetail Saw, the 12 inch Dovetail-Small Tenon Saw and the 16 inch Tenon Saw. Before I look at each saw and show how I use both the dovetail saw and a tenon saw, I want to discuss the two most important features of a saw, in my opinion. First, how well the saw feels in my hand and, second, how well the saw tracks in a cut. The saw should feel like an extension to your hand and arm and the saw should track in the kerf with no compensation by you while you are cutting. I find that all of the Bad Axe saws feel perfect in your hand and this is due to the diligence that they put into defining the best 'hang angle' for each saw.

What is the hang angle? The technical definition can best be explained by imagining a line drawn perpendicular from the back of the handle to the toothline. This is basically the angle formed between a saw's grip and its toothline. When you push the saw, the force travels in the direction the grip is facing so the hang angle has a profound effect on how well a saw cuts. If the angle is wrong (too high or low) you have to compensate while pushing the saw. The Bad Axe saws feel like they want to grab the wood and just plow through the cut. A perfect feeling!

The second critical aspect of a saw is how well it tracks while cutting. These saws grab the wood, as I've said, and stay on line in the kerf. Mark Harrell says this is because they hammer-set their toothlines instead of using a pliers-type set which bends the metal. I was watching a sharpening demonstration at the Bad Axe booth at a Woodworking in America (WIA) show and was surprised to see them set each tooth by hitting an anvil-like device with a hammer. I believe this precise set is what gives the Bad Axe saw its precision as it makes a cut.

Bad Axe 12" Stiletto Dovetail Saw

The Stiletto Dovetail Saw is 12 inches long rather than a typical 10 inch long saw. It has 15 ppi and is set for rip cuts since dovetailing is basically a rip cut. The blade is 1-3/4 inches (45mm) deep. I liked the extra 2 inches in length because I often stack multiple boards together when cutting dovetails.

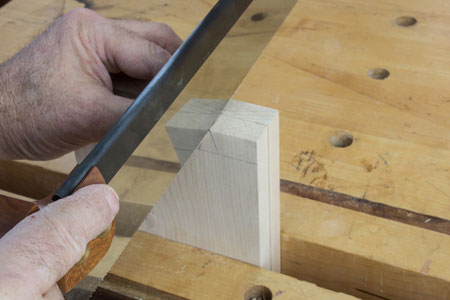

The photograph shows two boards clamped together so I can cut both tail boards at the same time. As an aside, if you look close in the following picture you can see I 'bend over' the corner of my knife line which helps to start the saw and 'split the line'.

The photograph shows two boards clamped together so I can cut both tail boards at the same time. As an aside, if you look close in the following picture you can see I 'bend over' the corner of my knife line which helps to start the saw and 'split the line'.

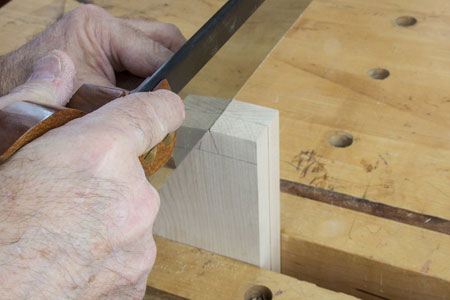

The Stilletto started extremely easy with the first push stroke...no bumpy starts or need for a pull-back stroke prior to the push stroke.

The Stilletto started extremely easy with the first push stroke...no bumpy starts or need for a pull-back stroke prior to the push stroke.

I was then able to define the kerf across the total width of the boards.

I was then able to define the kerf across the total width of the boards.

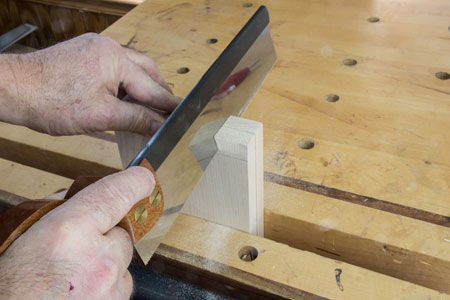

The longer blade seemed to track better than my personal 10 inch dovetail saw and I was able to get a longer, more powerful stroke as I was traversing down the side of the dovetail. I had plenty of room to make long clean strokes with no kinking or twisting.

The longer blade seemed to track better than my personal 10 inch dovetail saw and I was able to get a longer, more powerful stroke as I was traversing down the side of the dovetail. I had plenty of room to make long clean strokes with no kinking or twisting.

Once one side is done, you do the same for the opposite side!!

Once one side is done, you do the same for the opposite side!!

I found starting the Stiletto with its 15ppi toothline very easy in the maple boards and the extra length tracked nicely though the wide combination of boards.

I found starting the Stiletto with its 15ppi toothline very easy in the maple boards and the extra length tracked nicely though the wide combination of boards.

Bad Axe 12" Dovetail-Small Tenon Saw

The next saw is the 12 inch Dovetail-Small Tenon Saw. This saw has a 2-3/8 inch depth so it can cut larger dovetails than a conventional dovetail saw like the Stiletto. The interesting thing about this saw is the 'hybrid' set that Bad Axe has developed. The hybrid set is a combination set that lets you cut both cross-grain and rip. Therefore, it works really well on tenon joinery where you can now do both cuts with the same saw. Here is a typical layout for a tenon. I've used a marking gauge to define cheeks and shoulders for the tenon.

The next thing I do is create what Chris Schwarz calls a 'first degree cut' which means he defines a 'valley' into which the saw will drop so you can get a nice clean shoulder. The picture shows this valley partly cut. It is simply a small paring down to the knife line that the saw will fit into when starting the cut.

The next thing I do is create what Chris Schwarz calls a 'first degree cut' which means he defines a 'valley' into which the saw will drop so you can get a nice clean shoulder. The picture shows this valley partly cut. It is simply a small paring down to the knife line that the saw will fit into when starting the cut.

The hybrid cut of the tenon saw gives me a nice clean cut as shown in the following pictures.

The hybrid cut of the tenon saw gives me a nice clean cut as shown in the following pictures.

The following pictures show the remaining cuts to define the first half of the tenon. I found the hybrid cut on the tenon saw tracks nicely and creates a clean cut going either with or across the grain.

The following pictures show the remaining cuts to define the first half of the tenon. I found the hybrid cut on the tenon saw tracks nicely and creates a clean cut going either with or across the grain.

Bad Axe 16" Tenon Saw

Bad Axe 16" Tenon Saw

The third saw is the Bad Axe 16" Tenon Saw that is 16 inches long and also has a hybrid set at 12 ppi. (Some folks online have been calling it the Jack Saw.) If you are cutting large dovetails or larger carcass pieces, this would be the perfect saw.

I highly recommend these superb Bad Axe handsaws!

Jeffrey Fleisher has been a woodworker for approximately 20 years and a professional woodworker for the past 6 years. He is the president of his local woodturning club, the Woodturners of the Virginias and past president of the Northern Virginia Carvers. You can see some of the furniture he has made at www.jeffswooddesigns.com. He can be reached by email at furnmkr@gmail.com.

Return to

Wood News

front page

|