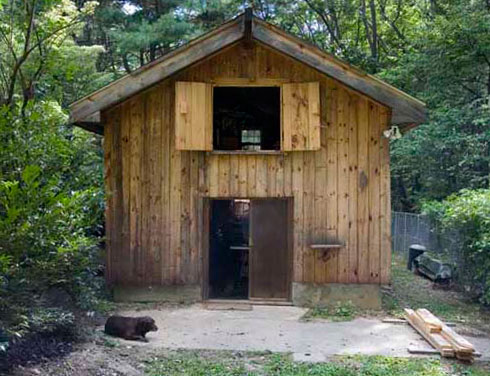

Here's My Shop!

by Luke Cabanel

Huntingdon Valley, PA

Random Woodworks is my woodworking business, located in this small timberframe woodworking shop

about thirteen miles outside Philadelphia. I built the shop with some help from one of my brothers

about five years ago. I produce custom furniture and often, one of a kind pieces for home and

business. I make furniture largely influenced by the Shakers along with Windsor chairs and I am an

avid woodturner. Although it is a one man shop much of the time, I often collaborate on larger

projects with my friend, Bob Longstreet, whom I met back in New Hampshire while we were both

taking a Windsor chair course at the Windsor Institute with Mike Dunbar.

The early part of this year Random Woodworks completed a commission for the Betsy Ross House in

Philadelphia. Bob and I built a Philadelphia style comb back windsor chair, a stool to match,

colonial style shelves and a replicated cutting table for fabric. The commissoned work is featured

in a new interactive exhibit at the Betsy Ross House where "Betsy" will interact with the thousands

of tourists who visit the house annually while at work in her upolstery shop. Shortly after being

featured in the Philadelphia Inquirer in late February, Random Woodworks was interviewed by

Solutions with Suzanne, a cable show with a national audience. The airing is set for this fall.

As you will see most of my equipment is on wheels for mobility. I would love to have the luxury

of a bigger shop (especially a separate room for finishing) and dedicated areas but for the time

being I do the best I can in my timberframe shop that measures 16' x 24' and a story and a half

high.

If you can piece it together from the pictures, when I get a commission I begin with milling

once the wood has acclimated to the shop for a bit. When I mill lumber I move my tablesaw outfeed

table over to my lathe, I then pull my planer out and do-see-doe it over to the tablesaw and hook up

the dust collection. You'll notice that my jointer is on a wheeled platform that lifts it about 4"

higher than the tablesaw side table so I have clearance for joining longer boards. My sliding chop

saw is also on wheels and it is on a base I made with wings that once pulled out get lifted and

supported with braces. The wings have slots where I connect stop blocks for repeatables. My 18"

bandsaw is also on wheels and moves back and forth depending on the length of the piece being cut.

Although a bit hard to see with so many offcuts covering it up presently, in the corner near the

lathe is my router table that is also---wait for it---outfitted with wheels. When needed it gets

pulled out and hooked up to dust collection. I know you're wondering what I do with all my spare

room. Upstairs I have workable space under the peak where my classic delta floor model drillpress

lives along with a spindle sander and an X/Y axis router table for cutting mortises. Closer to the

eves the space is used for storage-you know, stuff I'll never use but can't throw away.

Although I started my woodworking career as a kid carrying my grandfather's carpentry tools back

in New Hampshire, I took a detour through a Washington, D.C. law school and about eighteen years of

matrimonial practice here in Philadelphia before returning about seven years ago to doing what I

love. The business is certainly up and down, especially lately. But I am doing what I want to be

doing with my life.