Here's My Workshop!

by Michael Curtis

Columbia, SC

I designed and built this workshop with my wife, Tonya, in the summer of 2007. The exterior of my

shop was designed to blend in with the house and neighborhood. The shop can be converted to a guest

house, play room or pool house at a later date. The diminsions of the shop are 25' x 32', and it is heated with

10' ceilings and attic storage with a pull down ladder. The exterior is vinyl siding with aluminum

flashing. The columns are fiberglass. The shingles are architectural shingles.

There is a washroom and a storage closet housing the compressor, dust collection cyclone and a

lot of tools, hardware and miscellaneous junk. The walls are a board and batten design. The battens

are nailed right to the studs so finding a stud is never a problem. Even though the latest fad is to

use wallboard for shop interior walls, I feel like wallboard isn't durable enough for a shop. One

bang with a board and you have a big divet!

|

|

This is

my main workbench. It is 8 feet long and 30 inches wide. The table top is 36 inches from the floor.

This is where I do most of my hand tool work, inlay work and some glue ups. I built in a couple of

large storage drawers to hold my power tools.

|

|

|

|

My auxillary workbench is used to

hold tools and materials I'm not immediately using. The purpose is to help prevent my main workbench

from cluttering up. When I'm working, I stand between the main and auxillary workbenches. This puts

95% of what I need within easy access.

|

|

|

|

The ductwork for the dust collection system runs out

of the storage room, through the wall above the lathe. It branches off a spur to handle the table

saw, planer and jointer. The main line circles around the walls all the way around to the miter

saw.

|

|

|

|

The store room has nearly wall to

wall and ceiling to floor shelves. And STILL I manage to fill them up. My wife scribbled me a note

one time where she called me a packrat. Hmm... I think that note is on the third shelf on the

right.

|

|

|

|

The Sharpening Station and Scroll Saw are the two most

recent additions to the shop. I use the sharpening station to sharpen lathe chisels, plane irons,

chisels and whatever else needs sharpening. The scrollsaw is my daughter's favorite tool, and will

soon have a stand with drawers, a magnifying glass and a slightly larger table.

|

|

|

|

The shop is wired with 200 amp

service. All machines have a dedicated circuit including the HVAC and those machines that run on 110

volts like the router table, compressor, miter saw and drill press. In addition, there are four

individual

15 amp receptacle circuits and three separate circuits for the lighting.

|

|

|

|

A better view of the new lumber rack, which doubled

my lumber storage over the last one.

|

|

|

|

This is where I'll dream up

new projects to build.

|

|

|

|

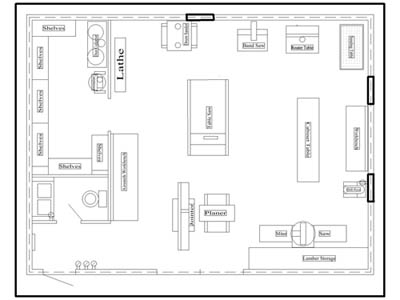

A Close approximation of the layout of the machines.

|

|

|

|

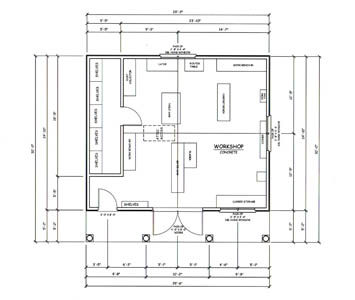

My wife's floor plan design.

|

|

Michael can be reached via email at

mcurtis@curtis-home.net

.

Return to

Wood News

front page

|

|