The Sweetheart Chisels: Stanley's Reissue of the 750 Socket Chisels

by Chris Black

Canton, GA

New Tool Joy

Good news! Stanley UK has reissued the 750 socket chisel. What's the big deal you say? Ask any

woodworking tool collector what the most sought-after bench chisels are and chances are many will say

the Stanley 750 series. The popularity of these chisels stems from several reasons. They are

Stanley products after all. Old Stanley tools have always been collectable, generally at reasonable

prices. Good publicity in the trade journals and blogosphere has also added to the mystique of the

750s lately. Lastly they are just good looking and good quality tools. As a result, Stanley's 750

socket chisels were the inspiration for Lie-Nielsen's excellent line of bevel edge chisels.

Currently the only drawback to used 750s is the price. The high prices are a result of increased

demand from all the good press these chisels get. On the used market an individual Stanley 750 in

useable shape can run $50 plus. What's left in the affordable range are beat-up, rusted tools with

missing handles. I always find the sockets mushroomed from repeated hammer blows when the handles

are missing. Given these facts, the Lie-Nielsen version looks like a deal starting at $55. But

as well made as the Lie-Nielsen chisels are, they are outside the budget of many woodworkers. So,

when I found out the new Stanley 750s (sold under the

Sweetheart label

)

were going to sell at a starting price of $30, I wanted to give them a go.

Let me tell you, I was pretty happy when I received 3 brand new Stanley 750s in the mail, sized

1/8", 1/4" & 3/4". These are the widths I use most during the workday for joinery and general paring

jobs.

New Chisel Preparation

After I got the chisels out of the box, I visually inspected them. The machining, although not as

refined as the Lie-Nielsen version, is certainly clean with tight milling marks as opposed to the

haphazard sanding swirls you find on economy tools. More on that later. I found the hornbeam

handles nicely turned and defect free.

Because socket chisels are prone to loose handles, I removed the handles to sand their tapers for

more friction in the sockets. Handle removal is easy. With the edge protector on, firmly grip the

blade and lightly rap the handle on a piece of soft wood. It should come off with little effort.

Some light sanding with some 150x paper removed the factory finish from the taper ensuring enough

tooth to grip the interior of the socket once the handle was driven home.

With the handles still off, I removed the shipping lacquer from the chisels by soaking them in a

soup can full of lacquer thinner. Five minutes was all it took to dissolve the film. A quick go with

a Scotch-Brite pad buffed away the last bit of residue.

There are many ways to reseat a socket chisel handle. My technique is simply to place the

cutting edge of the chisel on a piece of softwood and give the top of the handle a good bash with a

wooden mallet. No more to it than that.

I chose to flatten the back of these chisels with my 200 grit Japanese waterstone. Of course you

could use sandpaper on glass, a diamond stone or any other abrasive you like. I was pleased to find

that the 3/4" chisel only took 2-3 minutes to remove the factories milling marks and to get the

tool's back flat to my satisfaction. The small sizes took slightly less time. Nice.

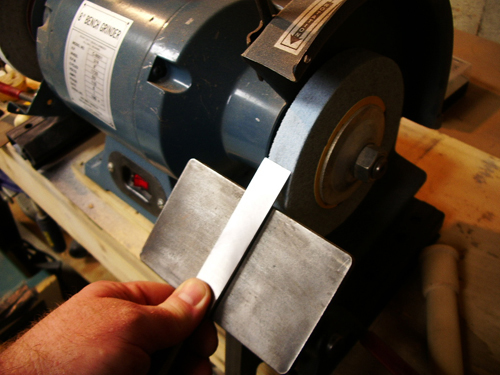

As for coarse sharpening and bevel shaping, I like a slow speed grinder (around 1750-2000 rpm's)

with a 60 grit aluminum-oxide wheel. The wheel pictured happens to be a Norton Blue wheel. The

bevel angle from the factory came in at 30 degrees. Right where I like it.

So, I eyeballed my Wolverine Jig to set the center of the bevel tangent to the wheel, and started

to grind. Now, let me say here that it is not necessary to do any power grinding. A good honing

guide and a coarse diamond stone, water stone or sandpaper will certainly do the same thing. The

point is to remove the factory milling marks, quickly adjust the bevel angle and move on to the next

finer abrasive. I promise the woodworking police will not come knocking if you have another

method.

I removed the grinding marks from the bevel and the 200 grit waterstone scratches from the back

with a 1000 grit water stone. I honed the bevel and polished the back with an 8000 grit waterstone.

That's it. I found these chisels tuned up much faster than all but the most expensive brands I've

come across. I spent no more than an hour preparing all three chisels. Now my standards are purely

practical. I didn't bother to make them pretty only functional. I need to get to work and push some

product out the door after all. You may choose to spend more time fettling your chisels. This may

include but is not limited to grinding the side bevels closer to the back (called stoning) and

polishing out the factory machining marks from the top and sides. By the way, these chisels took a

fine edge as you'd expect. I'll tell you how that edge held up in the next section.

Are They Any Good?

So, I've spent the last week using

Stanley's

reissue 750 socket chisels

in sizes 1/8", 1/4", and

3/4". I didn't set up any arbitrary test criteria or elaborate measuring devices to determine who

knows what. All I did is what I normally do with chisels during a workday in my cabinet shop. You

know, pare chamfers, clean out glue glops, chop joints and open paint cans. I'm kidding about the

paints cans. For that I use a pocketknife.

Anyway, over the years I've decided I want 4 things in a new bench chisel. It has to be well

machined from the factory - I can't afford to spend the entire day tuning it up. It must stay sharp

for a reasonable amount of time - The edge can't deform every time I hit it with a mallet. The

handles have to be comfortable and not prone to splitting or breaking. I'd like the tool to look

nice as well. I think a little care in form and design adds to the innate pleasure of using a fine

tool.

As I mentioned above, I found these new 750s to be well machined out of

the box. I got the backs flat quickly. You'd expect this from a premium tool. Were they as perfect

in form as, say, the Lie-Nielsen's? No, but the lower price of the Stanley's adequately reflects this.

After the initial sharpening, I only had to touch up each edge on either a strop charged with honing

compound or my 8000 grit water stone during this evaluation. This seems right to me based on my

experience with other premium chisels. They definitely held up better edgewise than any of the

economy line chisels I own. Now all this is purely anecdotal on my part of course, but I feel I've

gained a good grasp over the years on how long a chisel edge should last. As for the handles not

splitting, only time will tell. Hornbeam is pretty tough stuff after all. In my opinion, nothing

beats a socket chisel for looks and longevity. Socket chisels are definitely worth the extra money

compared to say a tang fitted handle.

Bottom line? I'm enjoying

Stanley's new 750s

. I feel the price to quality ratio is certainly

there. They are a great option if you've always wanted a set of socket chisels and either couldn't

find the originals or afford the ones on the used market. You'll have to spend a little more time on

these to get them pretty if that's important to you, but you'll save money. I, for one, look forward

to rounding out my collection with some fill-in sizes soon.

Here's a parting tip a friend suggested. While the handles are off, why not make a pattern by

tracing around one of the handles on a piece of scrap. Label the pattern and store it in case you

ever need to turn a replacement.

Chris Black makes cabinets, sharpens hand saws and sells old woodworking tools. Send him an email at

redscabinet@gmail.com

and follow him on twitter

@chrislblack

.

To see our full selection of Stanley Sweetheart chisels,

CLICK

HERE:

Return to

Wood News

front page