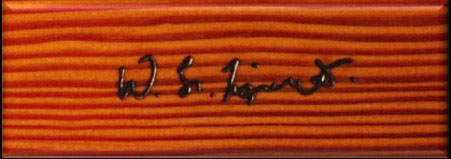

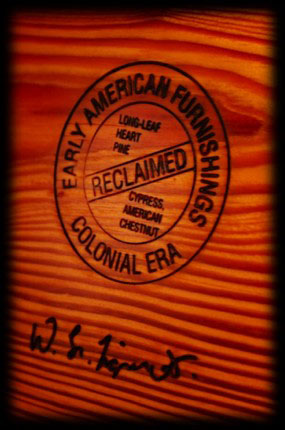

The Maker's Mark

by W. Lee Tigner Jr.

Dawsonville, GA

My clients often comment that their favorite thing about my work is my signature, which is a

branded emblem including literally, my signature. The reason for branding one’s work is worthy of

discussion. Branding is a sign of the maker, a distinctive mark that is unique to you, the artist. A

maker’s mark identifies the self and speaks from the soul of the craftsman. If you put your heart

into a piece, then your work is deserving of a mark. And it doesn’t really matter if the piece is

some masterpiece with hand cut dovetails or stunning inlaid marquetry. Skill level is irrelevant;

this is more about passion than production. If all you are doing is spitting out furniture parts

from a CNC machine then branding your work may not be necessary. But if you are the kind of

woodworker that feels a sense of loss when a piece is gone, or if you are they type of woodworker

that eyes the piece with admiration when it is complete, then a mark is not only appropriate, but a

necessity.

The art of branding will drive you a little insane until you unlock the secrets. And like

everything else woodworking, books, articles, and instruction are not nearly as helpful as trying it

repeatedly. You must start with a quality brand, and by quality I mean heavy duty. Typically, the

brand is cut out of a piece of copper with your emblem or signature. But not just any brand will

work well. A quality maker uses a thick billet, and in some cases doubles up the thickness of the

material to prevent the “dishing” of the brand. Over time, after repeated heating the emblem may

warp if it was made too thin. A good maker will compensate for this coming effect. Additionally, the

maker should be able to ascertain how small certain features of your mark can be in order to

maintain effective visual appearance. Take the brand maker’s advice; he has probably worked the

scenario through before.

So you found a guy who makes a good branding iron; I use Terry Desilets at

Custom Branding Irons, LLC

. You have come up with a good design

and now need to decide whether or not to get an electric model or a flame brand. An electric model

will plug in and reach the appropriate temperature in about 20 minutes. The flame brand will have to

be heated with a propane torch. Either will work fine but each has their advantages, electric being

convenience. The flame brand in my opinion produces a more authentic look. The brand will not be as

consistent across the image, meaning it will be darker and lighter in various spots. This lends to a

more handmade appearance, but this may not be what you are looking for. Bottom line, an electric

should produce a little cleaner image while a flame brand should make a more rustic image. For my

work, I decided to go with flame brands.

The first order of business is to get the thing hot – really, really hot. It needs to be red hot.

Flame brands can be heated with a variety of methods. A propane torch that a plumber would use will

work fine on a small brand but if your image is larger than about the size of a quarter you will

want to use something with more BTU’s. A barbecue grill will work but I have found that a Coleman

single burner propane camp stove is ideal. It’s small and portable, the fuel is cheap, and it puts

out a lot of heat.

Once the heating method is established, then experiment with various species. I soon realized

that different woods will brand in dramatically different ways. As a general rule, soft woods with

very low moisture contents will brand quickly, whereas very dense woods will take a little more

pressure. Hardwoods like oak and cherry seem to brand the easiest, and by that I mean once the brand

is hot, even pressure for three or four seconds produces a great brand. I work with a lot of

reclaimed Longleaf heart pine, and this is a little trickier. This species is full of pitch and the

heat will draw this out. It takes longer to produce a deep brand and the pitch will run out and

escape when the heat touches it. Not enough pressure or not enough time will cause a weak image and

you will have to sand it out and do it again. Wet woods like pressure treated or even air dried woods

that aren’t fully dry will require significantly more time with a hot brand applied than fully dry

woods. How will you know how long on any of the species? Well, that answer is a learn-by-doing sort

of thing, but I can tell you that it should smoke. A lot. When I brand my pieces I open all the

windows in the shop or do it on the porch because a red hot brand will cause the smoke to pour

off.

Now you have to clean up the image. There are a lot of ways to do this, and once again it depends

on species. If you are branding a species that has pitch, this will have come to the surface in a

crusty, gooey film all around the brand. Use a cabinet scraper to remove this. Hardwoods can usually

just be cleaned up with 320 grit or higher sandpaper. Do not use anything more aggressive than this

though as you will begin to remove the mark. Then use steel wool to finish the cleanup and apply

your finish. If possible, use a penetrating oil finish to restore any color that may have been drawn

out by the heat.

Now that all of this has been worked through, you will likely notice that the brand is darker and

deeper on one side. Maybe pressure wasn’t applied evenly or the brand itself wasn’t heated

consistently. This is ok; do not stress over this. This emblem represents your handmade craft. It

needs to be a bit imperfect. Early pieces made by the Tiffany Glass Company had a printed sticker

that was placed on the bottom. Realizing this was too impersonal, Louis Comfort Tiffany changed the

mark to a hand applied image that was more irregular. While our work may not be in the same league

as the finest art glass in the world, the passion from the maker is on par, and that is what the

maker’s mark reflects.

A final thought here; as you experiment with this you will look to your shop floor and see Fifi,

the wife’s Fox Terrier hanging out with you alone one day. You must resist the urge. She who must be

obeyed will not find your name with a hand plane permanently emblazoned on Fifi’s backside nearly as

funny as you think.

Don’t do it; although I hear it doesn’t really hurt the dog all that bad. They do it to cows,

right?

Lee Tigner is a Craftsman of Fine, Reclaimed Heart Pine Furnishings. He can be reached by email

at

lee@earlyamericanfurnishings.com

, and you can

take a look at his website at

www.earlyamericanfurnishings.com

.

CLICK HERE

to look at some of the branding iron options available at Highland Woodworking.

Return to

Wood News

front page