Veritas Double Edge Flush-Cut Saw - Tool Review

by Jeffrey Fleisher

New Market, VA

There is a tool that no one ever thinks about, but is extremely useful when it comes to making cuts flush to the surface or edge of a board. That is a Flush-Cut Saw and every shop should have one; you never know when you may have to cut a peg flush to a surface, moldings flush to the back of a cabinet, or hardwood edging to the edge of a piece of plywood. A flush cut trim saw has its teeth set on only one side so the flat side can be put down onto a board and not leave scratch marks along the surface of the board. I've used many shapes, sizes and 'stand-ins' over the years but I've never been satisfied with the condition of the surface that these saws leave behind. I've owned very flexible Japanese style flush cut saws and I've even tried using veneer saws that have minimal set. I've finally found one that satisfies all of my requirements in the Veritas Double Edge Flush-Cut Saw.

|

Veritas produces almost 200 hand tools for the woodworker but they are best known for their innovation and superior quality. The feature that caught my eye when I first picked up this flush cut saw was the thickness of the blade. The saw is approximately 11-1/2" long with a 4-3/4" blade that is 0.022" (0.6mm) thick with a 22 tpi Japanese style saw blade. Previous Japanese style saws that I've used had a 0.01" (0.25mm) blade, which was just too flexible and kept pinching and twisting when trying to make a cut. This Veritas saw blade maintains its shape and powers through a cut.

|

|

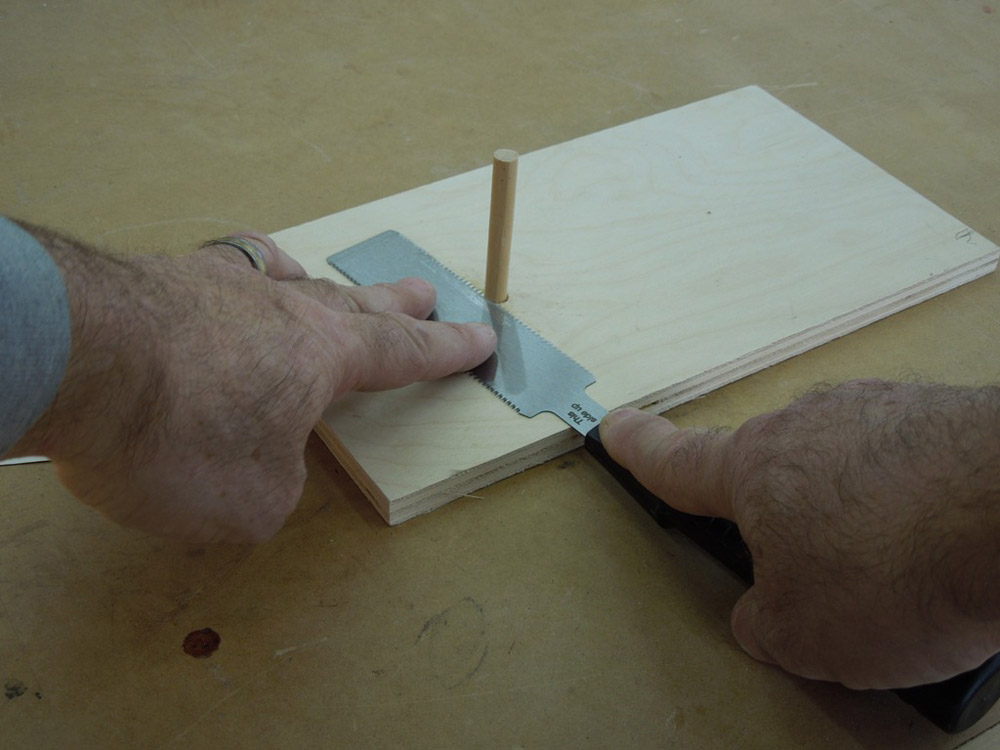

The traditional way to hold a flush-cut trim saw is to grasp the handle, place the blade flat onto the surface, and raise the handle to exert force down onto the blade while keeping it tight to the surface of the board. This was probably necessary with the thinner blades to keep them flat to the surface of the board but I've always had a problem with this because you are trying to both press down and move forward and backward at the same time. This led to scraped surfaces and kinked blades! With the Veritas saw I prefer to keep the blade flat to the surface and the handle relatively flat as well, picking it up just enough to not hit my fingers on the edge of the board. If necessary, you can place a couple of fingers from your other hand onto the blade to keep it tight to the surface of the board. This method allows me to only worry about pushing the blade forward and backward. The blade cuts on the pull stroke and I get no kinking on the push stroke.

|

The double-sided blade allows for optimal cutting independent of the orientation of the wood. You can get into tight spots and cut either end of a board, i.e, the edging on the edge of a plywood board, by just flipping the saw over. One trick I do, however, is to try and cut away from my off-hand. In other words, if I'm holding the saw in my right hand and the fingers from my left hand are on the blade surface then I like to cut from left to right as shown in the picture below. This way I can see where I'm cutting and am less likely to break through at the end of the cut and cut myself!

|

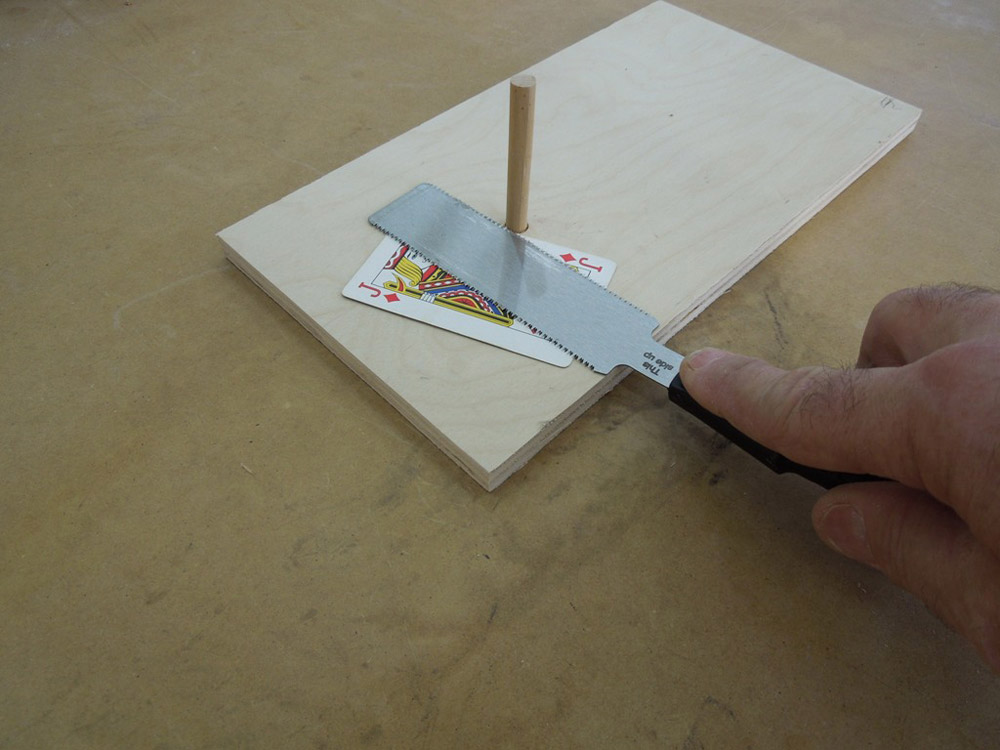

Finally, if I'm really worried about marring the surface of the board that the saw is on, then I'll use one of my other 'go to' tools in my shop, a deck of playing cards. The slick surface of a playing card provides a nice, thin, low friction shim between the blade and the wood. This will protect the surface and the small amount of wood left behind can be easily pared away with a chisel. Although I've used this technique in the past, I seldom have to do this with the Veritas Double Edge Flush-Cut Saw.

Veritas has once again developed an innovative and quality tool for the woodworker's shop. This saw demonstrates the commitment that Veritas puts into its product, even down to the "This Side Up" note stamped into the blade to make it easy to pick up and use.

Purchase your own Veritas Double Edge Flush-Cut Saw today!

Jeffrey Fleisher has been a woodworker for approximately 20 years and a professional woodworker for the past 6 years. He is the president of his local woodturning club, the Woodturners of the Virginias and past president of the Northern Virginia Carvers. You can see some of the furniture he has made at www.jeffswooddesigns.com. He can be reached by email at furnmkr@gmail.com.

Return to

Wood News

front page