|

|

Figure 1 - The completed

project

|

I have found that in my woodworking "career" I get into one thing or another and

stick with that until it starts to bore me or I get the bug about something else. I have

gone through a pen-making stage, a bowl-turning phase, a boomerang phase and a

Platonics-solids phase. Lately I've been in a walking stick phase and my most recent

project was a "crooked cane." It's great for rough roads and broken sidewalks in

case you were wondering.

It is mainly made of 1-1/4" square mahogany but the top square section is walnut.

The upper round disc is 1/4" by 2-1/4" diameter tulipwood and the lower round

disc is ebony. The handle is a recycled door handle from a local building materials

recycling center. As usual, I "signed" it with my branded maker's mark. This time,

though, I added a copper plaque with my email address just in case I walk off and

leave it in a restaurant someplace.

|

|

Figure 2 - Detail

|

Early on, I knew that I would need to reinforce the various joints in the piece.

Wooden dowels were the obvious choice but I decided that I wanted to be even

more certain of the strength of the joints. Instead of wooden dowels I decided to use a

3/8"-16 threaded steel rod. For those fellow woodworkers who may not be familiar

with it, this is a steel rod threaded all the way from end to end. It is sometimes

referred to as "all-thread." It is available in various sizes at most "serious" hardware

stores. (Be on the look out for my future article on threading, tapping, tap drill sizes, etc. It should be of interest to many

woodworkers).

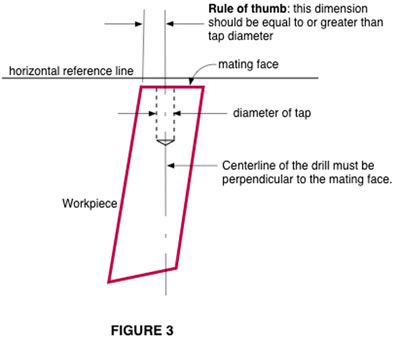

To start, I drew the walking stick full-size on a large sheet of paper. Doing this

enabled me to determine the various section lengths and to set my bevel square to the

angles of the different sections - and from there to the miter gauge on my table saw.

After cutting the various sections, it was time to drill and tap each section for the

threaded rod. The hole location for each section varied depending on the angle of

the section but was determined by an old rule of thumb as shown in Figure 3. Note

also that the hole size (also referred to as the

tap drill size

) for the 3/8"-16 threaded

rod is 5/16".

|

|

Figure 3

|

It was also very important that the hole and the subsequent tap be perpendicular to

the mating surface of each section. See Figure 4 for the drill press setup that I used. I

used the

Starrett Double Square from Highland Woodworking

to align

the work surface perpendicular to the drill. I drilled the hole about 1-1/2" deep in

each cane section. (Note: the depth will also depend on the angle of the section. You

don't want to break through the side, of course).

|

Figure 4 - Note that drill must be

square to mating face.

|

While I still had my work-piece clamped in place for drilling I left it in place so that I could tap it using the same setup. I replaced the

5/16" drill with a 3/8"-16 tap and tapped the hole as shown in Figure 5.

Do not do

this by turning the drill press on!

Simply use the drill press down-feed lever to

maintain a steady, even pressure while at the same time turning the tap with a pin in

one of the chucking holes. Alternatively, you can assure that the tap is square to the

work surface by using a simple tapping block as shown in Figure 6.

|

Figure 5 - Turn the tap using a pin

while maintaining a steady

downward pressure on the drill

press down-feed handle.

|

|

Figure 6 - Homemade tapping

block (about 1/2" thick) helps keep

tap perpendicular to the work.

|

When all of the cane sections have been drilled and tapped, cut pieces of 3/8"-16 to

length (mine are about 2" long) and insert them into the various cane sections. Then

test assemble each section. Note: the sections will probably not thread together in

the proper orientation for the finished cane. Do not force them to do so; if you do,

you may strip the threads. Instead, carefully sand or file a small amount from one of

the mating surfaces until you get the desired orientation. See Figure 7.

|

Figure 7 - Mating sections may

not align properly when threaded

together. Sand or file mating

surfaces until sections align

properly.

|

When you are satisfied that all the joints meet with the proper orientation, apply

System Three T-88 Epoxy

to the holes and the threaded rod

and screw them together.

I mounted the cane handle using the same drill, tap and threaded rod technique that I used

for the cane sections.

I drilled the cane end from a short piece of 3/4" dowel and added a crutch

tip, which is available at most hardware stores.

You can email Paul at

pburri@cox.net

.

Return to

Wood News

front page

|