|

I have been woodworking for over 25 years. I've been using a ruler since....well, for a LONG

time. I was working for the Federal Government during the late-70's when they tried to make the

switch from imperial measurement to metric measurement. So why am I switching now? I think it makes sense,

but it has been hard.

I've always thought, "There must be a better way to find half of 3-5/8", for example, when

marking the center point on a board. Sure, I can take half of 3 which is 1-1/2 and then add that to

5/16" by taking 1-8/16 plus 5/16" which equals 1-13/16"...whew. Instead, I can hunt around the shop

for my fraction calculator and plug in the numbers and presto! - out comes 1-13/16". Now, if I needed

half of 92mm (which is equal to 3-5/8") it would be 46mm. Easy right?

About 6 months ago I decided to transition my shop to metric instead of imperial. I thought it

would be easy and in some respects it is very easy and in other respects, it is very hard. I'd like

to take you through my experience and even though the experiment isn't over, I can provide some

interesting insights in case you are thinking about switching as well.

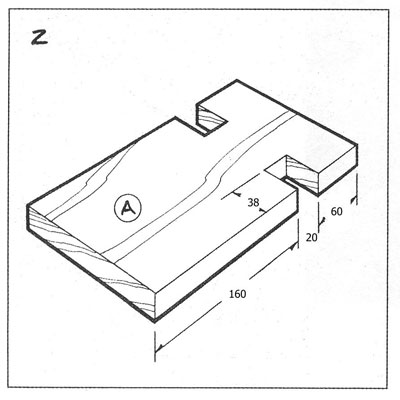

Again, let's take a look at why I made the switch with a couple of examples. I teach a

Woodworking Fundamentals class at a local hardware store and we make a small DVD/book holder as the

project. One of the first things we do is take a board and layout the first side which includes cutting a

notch partway along the edges and then cutting the board to final length. It looks like this:

Is it obvious that the overall length of the board is 9-1/4" long? No...well it isn't obvious to my

students either. When I start adding up the dimensions: 6-1/8" + 3/4" + 2-3/8" I look around and get a

bunch of blank stares from all my students. This is not an unusual situation in my shop as well. I am

often adding and subtracting dimensions to find overall lengths, shoulder set backs, centers between

edges, etc, etc. Where is my trusty fractions calculator?!

Now, what if the layout looked like this?

It is pretty obvious that the overall length is 240mm. No need for that calculator now....it can sit

in the corner and collect sawdust!

Now, let's take a real life example from your shop. Say you have a drawer front that is 25-3/8"

wide and you want to install drawer pulls equal distance in from each side and twice that distance

between them. You just need to divide 25-3/8" by 4. Hmmm. 25-3/8" divided by 4 equals 203/8"

divided by 4 which is 203/32" which is 6-11/32". Time to find that calculator again! But if the drawer

front was 644mm then 644mm divided by 4 equals 161mm.

I think it is pretty obvious why I want to make the transition to metric. It turns out that there are

two aspects to the transition. The first is the "physical switch", meaning the change in the equipment

you have to work with. The obvious one is the set of rulers, or measuring devices, that you use in your

shop. This is easy. I like using the

Woodpecker set of rulers

and the

Fastcap ProCarpenter Tape Measures

and have used them for years. Buying a set of metric rulers from them was easy with no

sacrifice in quality.

The same is true with switching drill bit sets, screws and all those physical things that may cost

a little bit to make the switch but it is worth it... Finally, tools like my

SawStop Table Saw

already

come with a combination imperial-metric tape measure to set the rip fence.

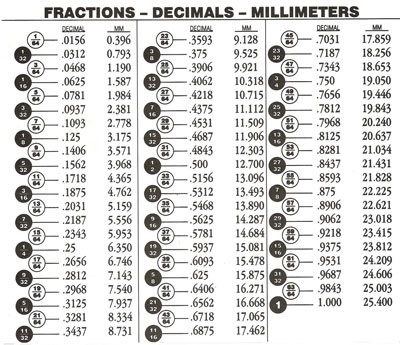

I also posted a imperial-metric conversion chart on the wall in my shop thinking that it would

help with the transition.

Posting that chart on the wall was my introduction into the second aspect of transitioning to

metric – "Thinking in Metric." What does 25.4mm look like? Well, it is an inch. What does 3mm look

like...or 300mm? When you have grown up in an imperial measurement world you don't have that

mental picture in your head about what measurements look like. If I say to you, "how big is 1/8" or

1/4" or 12" or 6'4"....you know. But what about their metric equivalents...3mm, 6mm, 300mm or

1930mm. I never knew that I was 1930mm tall! I "think" in imperial measurements. This is the part

that I said was very hard....thinking in metric. When I want to design a piece of furniture I want to

think that I need a 3mm apron setback from the edge of the leg and not have to think 1/8" and then

convert that to 3mm. I didn't have that mental picture of what a metric measurement looks like.

Ahh, using metric rulers will help, right? I thought so too but they require some getting used to

as well. The following picture shows a combination ruler with both imperial and metric scales. If your

measurement was 16 inches, that is pretty easy to find. But what about its equivalent which is

406mm? It doesn't jump out at you. If it is a pure millimeter tape then it will show the 100 millimeter

positions as powers of 100...100, 200, 300, 400 etc with 10 millimeter between them 10, 20, 30, 40 etc.

So, to find 406mm you look for 400 and then move over 6 millimeters.

If all this sounds confusing, it really isn't. It's a matter of getting used to envisioning things in a

different way. The metric system is easy to use. It's very logical and is derived from a base-ten

calculation, which makes its addition, subtraction, division and multiplication very easy. Right now, I

am finally getting that mental picture about what 3, 6, 9, 12, 19, 25, 150 and 300mm look like. I think

with time I'll have the mental picture that a 48" wide cabinet is really 1220mm. So, my

recommendation is to try and build a small project using metric measurements. Once you start, you

may not want to go back to fractions and inches either.

Jeffrey Fleisher has been a woodworker for approximately 20 years and a professional woodworker for the past 6 years. He is the president of his local woodturning club, the Woodturners of the Virginias and past president of the Northern Virginia Carvers. You can see some of the furniture he has made at

www.jeffswooddesigns.com

. He can be reached by email at

furnmkr@gmail.com

.

|