|

Old Iron

If you have read any of my early submissions here in Wood News and to the

Highland Woodworking Blog, you will know that I am a really big fan of vintage woodworking machines. I love them.

It started out as a question of economy. When first outfitting

The Tiny Shop, I was very strapped for funds. I had, at one time or another, used or owned more modern versions of the tooling that currently is in use in my shop. I knew what I needed, what I wanted, and what would be "nice to have." Finding older, "vintage" versions of these machines seemed to be the best option financially, to get up and running at bargain basement prices.

As it turned out, I was able to knit together a really snazzy group of machines that work well for me for the type of work that I do. Add to that the nostalgia and the "feel" of these machines, and I am now hopelessly in love with the "old 'Arn" (Old Iron), as we vintage tool junkies call them.

Now then, rational thought and good judgement had been dictating to me that my 1946 Delta, Art Deco bedazzled base, jointer was perfectly capable of handling all my needs in The Tiny Shop. Without question, the machine performs flawlessly. Lovely clean cuts, and spot on accuracy. A real delight.

|

However, with talk of building a larger "Tiny Shop" between my wife and myself, and an opportunity to acquire a larger, more vintage jointer coinciding, I took the plunge and made a deal on the jointer pictured below.

|

|

Behold, a 1909 Crescent Machine Co. 12” jointer. Replete with Babbitt bearings, and a gross weight that rivals a Sherman tank. This machine is ….how do I put this delicately….STOUT.

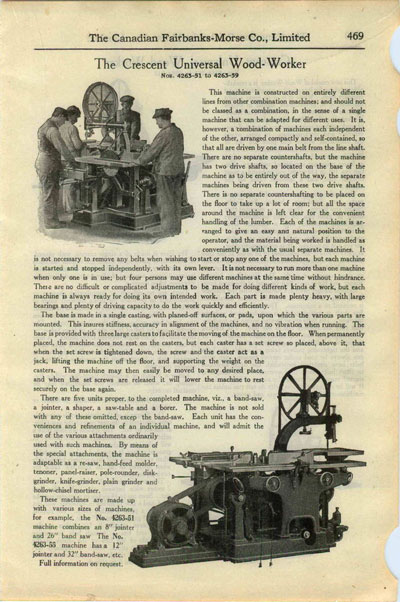

It was a part of a set up called "The Universal Woodworker" made by the Crescent Machine Co. Something like an early version of the modern European combination machines of today, only way, way, WAY bigger and more heavily cast.

|

She has 12" wide tables, 65" long. A two knife cutterhead, and, because this came off the "Universal Woodworker" it also has a bit of an iron outcropping with a spindle hole in the outfeed table. One that might just be perfect to hang a nice, big,

Triton Router

under.

Crescent Machinery was eventually bought by Delta Rockwell, so I am just fine with keeping things "in the family" so to speak.

I know it sounds like madness to swap out a 6 inch jointer for one that has twice its capacity in a shop coming in at 250 square feet. Trust me, I had to really work hard to wrap my head around it too. As it turns out though, the only dimension that really changes is the length of the tables, by quite a bit I admit, but not so much as to limit my workflow or to cause the need for any gymnastics when jointing pieces.

Miraculously, it is a perfect fit for both the shop space, and for my work habits.

I will not gloat by revealing what I bought this machine for. Suffice to say it was a VERY low number. The previous owner was switching from working wood in retirement, to working on classic cars, and wanted this thing GONE.

I am excited to get this thing into my shop soon. The purchase price included it being shipped to my house by the previous owner, as he has a child that lives near me. His visit with her, and the delivery of my new-to-me, Nimitz class, jointer should be happening just about the time you are reading this.

To say I am like a kid on Christmas morning is putting it mildly…...I'm giddy.

I will plan to do a follow up on this once I get it here and tuned up. Watch this column in the coming months.

John McBride is a professional woodwright, blogger, and writer, living and working joyfully and with abandon in Denver, Colorado. He welcomes feedback and connecting with those who read his ramblings, and can be reached

at madcapwoodwright@gmail.com. Feel free to drop him a note.

Return to the Wood News Online front page

|