Making a Wooden Globe, page 3 of 4

by Marco Aurelio R. Guimaraes

marcoarg@terra.com.br

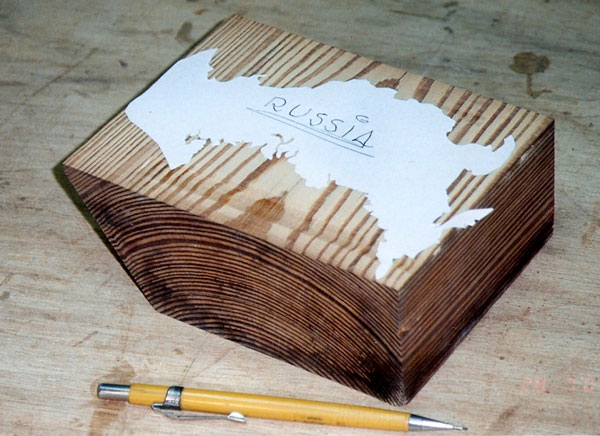

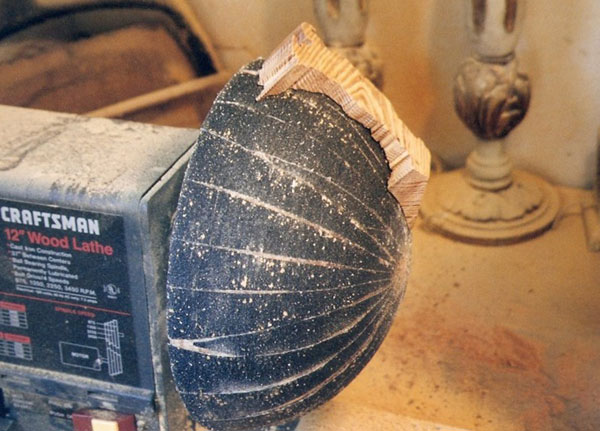

The convex pieces that form the landmasses were made from small, thick blocks, as illustrated in the

series of photos which follow.

The shaped landmasses, after being glued together in their proper boundaries, were then carved in

order to suggest the topography and the most important geographic

features.

At a scale of 1:40,000,000, Mount Everest, for instance, would only be about .009" high. That is why

the vertical scale is only suggestive rather than represented literally. In this way I tried to

represent the most important mountain chains, larger lakes, main rivers, islands, and general

geographic features that I could best detail.

The carving and whittling work was based on the atlas and map sources previously cited, and are an

attempt to best represent (or at least suggest) the topography of the countries around the world.

This work was done using very small chisels, dental power and hand tools, chip carving knives,

mini-rotary tools, and many types of whittling and sanding tools.

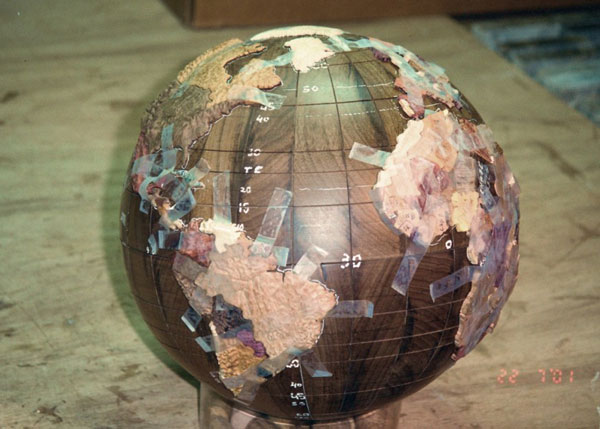

Although the vertical scale is not precise, the horizontal scale must be precise. Otherwise the many

country boundaries would not match perfectly and the relative position of the countries would be

affected, severely diminishing the accuracy of the whole work. Thus in order to avoid mistakes in

positioning the continents, islands, polar regions, etc., these pieces were first dry assembled

using clear tape. After provisionally dry-fixing all pieces onto the surface of the earth globe, I

marked the outline of the pieces with a sharp pencil to make the final gluing job easier.

Even assuming that all care was taken in each step in an effort to maintain the smallest possible

tolerances, some new problems surfaced after the pre-assembly of the landmasses on the globe.

Through the north and south pole, I inserted a long 3/8" brass axle with two ball bearings to allow

smooth rotation of the globe. This axle protrudes from the poles about half an inch. Both ends are

solidly fixed by a decorative cast silver piece in a large metal ring that permits the orthogonal

rotation of the assembly. Due to several causes, but mainly because the earth globe has on its

northern hemisphere much more continental mass than in the southern half, the wood globe was

completely unbalanced and tended to stay upside down.

In order to balance the weights of both hemispheres, I embedded some lead weights inside the two

semi-spheres of the wood globe, similar to how a car wheel is balanced. Using the method of trial

and error, I had to position another small weight at a specific point so that the final inclination

of the N-S pole line was 23.5 degrees, which is the proper ecliptic angle. This is the inclination

of the N-S earth axis in relation to the plane of its orbit around the sun.

With these arrangements, the globe could then twist simultaneously in the two orthogonal directions,

one movement not interfering with the other and always stopping in an upright position, at the

ecliptic angle relative to the plane of the biggest horizontal wood ring.

The metal and wood rings were graduated every 5 degrees so that it would be possible to find a

particular point on the globe just by knowing its correspondent coordinates, which is to say, its

latitude and longitude.

Regarding these rings, the metal one was turned in brass, on which the ornamental designs were

carved by hand using a burin. Finally, the brass ring was plated with a 10-micron layer of 18-carat

gold. This finishing was used in every metal piece of the assembly except the internal part of the

N-S brass axle. All other metal parts were carved in wax and cast in silver before receiving the

gold covering layer.

The horizontal wood ring actually is a bent lamination of 37 strips of about .04" of Jacaranda (

Dalbergia nigra — or Brazilian rosewood) and Pau Marfim (Balfourodendron riedelianum -- or ivory

wood).

This ring must be very strong because it supports the entire weight of the globe as well as the

heavy brass ring. I did not want a ring made of a solid piece of wood that would naturally have had

a grain direction and thus could not distribute the forces evenly along its perimeter. Another

important issue to consider was the fact that only four thin columns would support the entire weight

of the assembly. In adopting the use of solid wood for this project, I would certainly have warping

problems, among others, such as cracking and splitting. The bent lamination was naturally the best

solution for this problem and the process of assembling and gluing the ring is self-explained in the

following sequence of photos.

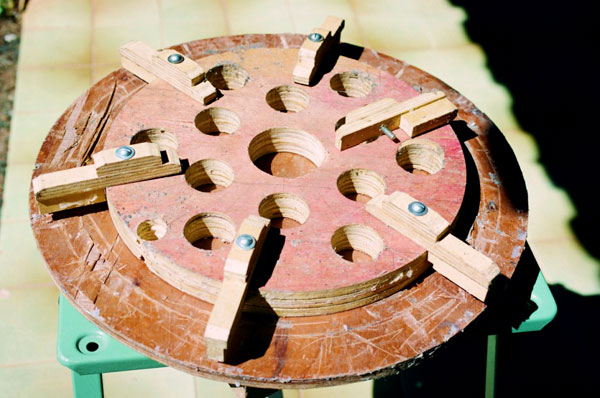

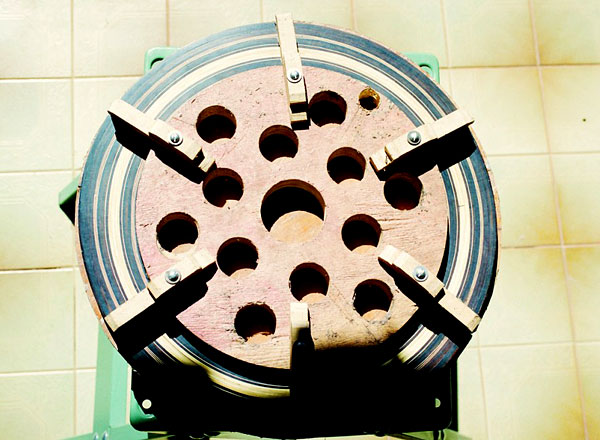

The circular plywood jig with unaligned holes made it easy to fix and maintain the strips in the

right place during the gluing process. Even using this small trick however, the lubricating effect

of the glue made the strips tend to slip upward, which forced me to upgrade the jig by assembling

radial cleats that could then maintain the strips in place.

Since Brazilian Rosewood is a very dense and extremely hard wood species (similar to Gabon ebony),

it is also brittle. Thus, in order to diminish the struggle with such a stubborn wood, I had

previously immersed the 3/4" x 3/64" strips in water for about three days. Then with the use of a

hot air blower, it was possible to tame them, allowing me to roughly obtain a circular shape and

easily accommodate them in the jig.

In the wood ring at 0 degrees and 180 degrees of longitude there are two bearings also cast in

silver that support the weight of the entire piece.

Go to final page

Go to Wood News front

page

Go to previous page