by Steven D. Johnson

by Steven D. Johnson

Racine, Wisconsin

This month:

•

Switchable Magnets & Featherboards

•

Advertise Your Workshop & Woodworking!

•

More Remodeling Surprises. Some Funny, Some Not So Pleasant!

•

A Couple Of More Things

Switchable Magnets & Featherboards

Click on any picture to see a larger version.

Do you use featherboards and other work-holding devices in conjunction with your power tools?

Do you make your own featherboards or do you use the off-the-shelf clamp-in-the-miter-slot kind?

Gut-check time…

The answer to the first question, as you know,

should

be "yes," but for many of us the improved accuracy of the cut and the additional safety provided by featherboards and other work-holding devices sometimes takes a back seat to the harsh reality that using them takes too much time.

The answer to the second question is, "it doesn't matter." Whether you make your own or use commercially available featherboards, you have probably been somewhat disappointed by the results, the "finagling" it takes to make them work, and… they take too much time.

Let's face it… the featherboard device set-ups that require we wedge, screw, or jam something into a miter slot is a somewhat flawed concept from the get-go. The miter slot will almost always be in the wrong spot, and whatever method we use to wedge or clamp something firmly into a slot designed for sliding is sure to be problematic. I have had a bunch, still have a few, but commercial featherboards have all, to some extent, come up short.

|

Figure 1 - The MagSwitch woodworking

line-up of products

|

When Highland Woodworking asked me to take a look at the

MagSwitch lineup of featherboards and work-holding devices

, frankly, I dragged my feet a bit. My rationale was simple. I figured I would waste a whole lot of time experimenting with the things and wind up not doing a video at all, simply because they were, like other commercially made devices I've tried, lacking. Instead, I found myself actually

using

the various MagSwitch components because they work, they are simple to use, they do not depend on a miter slot as a method for holding them in place, they take almost no extra time to set up, and they work… did I already say that?

The folks at MagSwitch use some sort of proprietary, and frankly, magical, technology to make a tenaciously strong magnet hold like crazy when switched "on" and release smooth as butter when turned "off." I'm sure some of the smart Wood News Online readers could explain the science behind it, but I don't really care. They work!

Highland loaned me a dozen different MagSwitch products, but I started like (I think) most people will, with the

MagSwitch Starter Kit

. The Starter kit includes two 150 pound MagJig switchable magnets, a Universal Base, a Reversible Featherboard attachment, and assorted screws, spacers, and knobs. Each of the primary components is available separately, but more about that later… first, a little bit more information about the magnets.

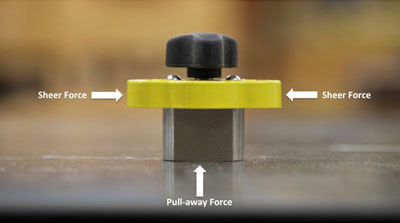

Two different strength MagJig magnets

are available for general woodworking applications. The 150 pound MagJigs are included with the starter kit. There are also 95 pound MagJigs. The "pound" designation refers to the rated "pull away" force the magnet can withstand. The thing we are mostly interested in, as woodworkers, is "sheer" strength (see photo for my differentiation of "pull away" versus "sheer" forces). "Sheer" represents the force, most of time, that MagJig magnets will need to resist so the various work-holding set-ups don't move.

|

Figure 2 - The MagJig magnet and the directional forces

it needs to resist

|

|

Figure 3 - Once locked down, even a pretty hard

hit won't move the jig

|

I did not have a reliable way to measure the "sheer" strength of the magnets, but it was impressive. When locked down to the cast iron top of my table saw, jointer, or band saw, the various configurations of hold-downs and feathers never moved one iota. I tried hitting them, pushing them, and knocking into them with a piece of wood, and they did not move. Could I move them? Of course. But it required force way above what might be encountered under normal use.

Both the "sheer" and "pull away" strength of the magnets can be negatively impacted by dirt, sawdust, oil, or wax on the tops of your metal tools. If you typically pour the oil or wax onto your cast iron and steel tools to fight rust, you may want to wipe off the tops before using MagSwitch products in order to get maximum magnetic adhesion. No need to remove it all, but the surface should be clean. The magnets should also be checked before use to make sure there is nothing on the bottom that could interfere with the magnetic hold.

The "switch" in the MagJig actually turns and aligns or "un-aligns" some mysterious force in the magnet, so it is not a measly 1/8 turn, there is no "click" to tell you when the magnet is fully engaged… in other words, it is not like a light switch. To engage the magnet, it requires a full 180 degree clockwise rotation. Likewise, disengaging the magnet is a full 180 degree anti-clockwise turn. Not turning the switch the full distance will result in the magnet not fully releasing or not holding well. Be sure to turn it until it stops and you are good-to-go.

|

Figure 4 - Lock any MagSwitch jig or assembly

into place, anywhere on any steel or cast iron top,

with just a twist of the switch

|

The Starter Kit will allow you to configure a feather board with the "feathers" set up for left-to-right or right-to-left feed, so on the table saw it will work with left and right tilt saws. Of course you can use the Starter Kit set-up on any ferrous metal table or fence, so you will likely find uses for it at the jointer, on a drill press table, or on the band saw (like ripping super-thick boards at the band saw, which I do a lot).

|

Figure 5 - The Starter Kit includes the core of the system,

the Universal Base, and the Reversible Featherboard

|

A lot of additional functionality can be added to the starter kit by purchasing the

Vertical Featherboard With Riser

. With this option the enormous potential of the MagSwitch system starts to unfold. Assemble the parts one way, and you get a jig that not only holds a work piece against a fence, but also holds it down to the table top. I sometimes need to saw a panel from 1/4" plywood, and that stuff is always wavy. Holding it down flat to the top of the table saw places my hands way too close to the blade, so this has been a welcome addition to my arsenal of safety and accuracy accessories. Assemble the Vertical Featherboard attachment a different way, in its "stacked" configuration, and the jig becomes a double-high featherboard that proved very effective at holding work pieces against the jointer fence when edge-jointing.

|

Figure 6 - Here I am turning the switch "on" to attach the

Universal Base with optional Vertical Featherboard in the

stacked position to hold a work piece perfectly upright

against the jointer fence

|

With the

Universal Base

and a little experience, the sky becomes the option. MagSwitch makes a ReSaw Guide, a Dual Roller Guide, and a Thin Stock Jig/Rip Guide Attachment that each attach in a similar fashion to the Universal Base. You can find all of these

attachments here

. The potential uses are simply too numerous to list here, but the

Product Tour Video

shows some ways these options can be used. We have also created a one-page guide to the MagSwitch product line that shows some of the various ways the system can be set-up and used. You can

take a look at the various Magswitch clamp combinations by clicking here

.

|

Figure 7 - The ReSaw Guide, the Dual Roller Guide, and the

Vertical Featherboard attachments all have adjustments to

dial in perfect vertical alignment

|

After using the MagSwitch products for a while, you will likely realize two important things… First, you will use the MagSwitch featherboards and hold-downs more than any others you have had in the past, simply because the MagSwitch products are easy to use, they can be positioned anywhere, and they are not reliant on a miter slot. Second, you will find that adding and removing various optional attachments to the Universal Base can be a bit time-consuming.

Fortunately an additional Universal Base and magnets are relatively inexpensive (less than $19 as of this article for the Universal Base and about $35 each for the 150 pound MagJig magnets) so as you learn more about the system and find more uses for it in your shop, you can buy additional bits and pieces and leave some configurations set up all the time. For example, I do enough resawing that I am going to dedicate a Universal Base and the Resaw Guide to my band saw. I will get another Universal Base to use for other configurations at the table saw and jointer.

|

Figure 8 - Drill a hole, affix a MagJig magnet and

quickly make any custom jig you can dream up!

|

In fact, if you find the featherboard indispensable at the table saw (and you will) another option is to buy a

Pro Model all-in-one Featherboard

with integrated MagJig magnets and simply dedicate that to use at the table saw. You can also attach the Vertical Featherboard to this whenever it is needed. Likewise, if you need a featherboard that can be used bi-directionally and want to use your Universal Base on another jig, you can purchase the Universal Featherboard. It, too, is an all-in-one unit with its own MagJig magnets. There is even a

Pro Fence Featherboard

with integrated MagJig magnets that can be dedicated to any steel or iron fence. You might want to dedicate one of these to your jointer.

Perhaps the most exciting aspect of the MagSwitch system is that MagJig magnets can be used to make your own special-purpose jigs. Drill a 30mm hole for the 95 pound MagJig magnet or a 40mm hole for the 150 pound magnet in 3/4" thick stock, and you can make any jig you can dream up. Often I make temporary jigs when doing repetitive operations. My temporary jigs usually involve scraps of plywood, wood screws, and lots of clamps to hold the jigs in place. I am looking forward to my next temporary jigs being held conveniently and firmly in place with MagSwitch's switchable magnets.

(Page 1 of 4)

1

2

3

4

Next Page

Return to

Wood News

front page